Description

Precision: High precision, assuring quality in the final cut

- Pre-tensioning system that reduces maintenance, and makes wire replacements easier and faster;

- Tensioning system that enables precise and parallel movements of the pulleys, providing constant and correct tension of the wire;

- It has two pre-programmed pressures, promoting the increase of the wire lifetime, and keeping the cut quality

- Wire-Guide Rollers with independent operation, boosting the cutting performance and lifetime of the diamond wire and rubberized wheels.

- Sealed Tensioning Wheels, avoiding damages and waste due to wire breaking.

- Tensioning Knife manufactured in wrought steel and processed in a constructive way that guarantees 100% of the adjustment, alignment, and efficiency of the equipment

- Designed to reduce the cutting time, decreasing the operational cost due to the efficiency of the hydraulic system and set.

- Allows the material cut in different thicknesses: 15, 20, and 30 mm.

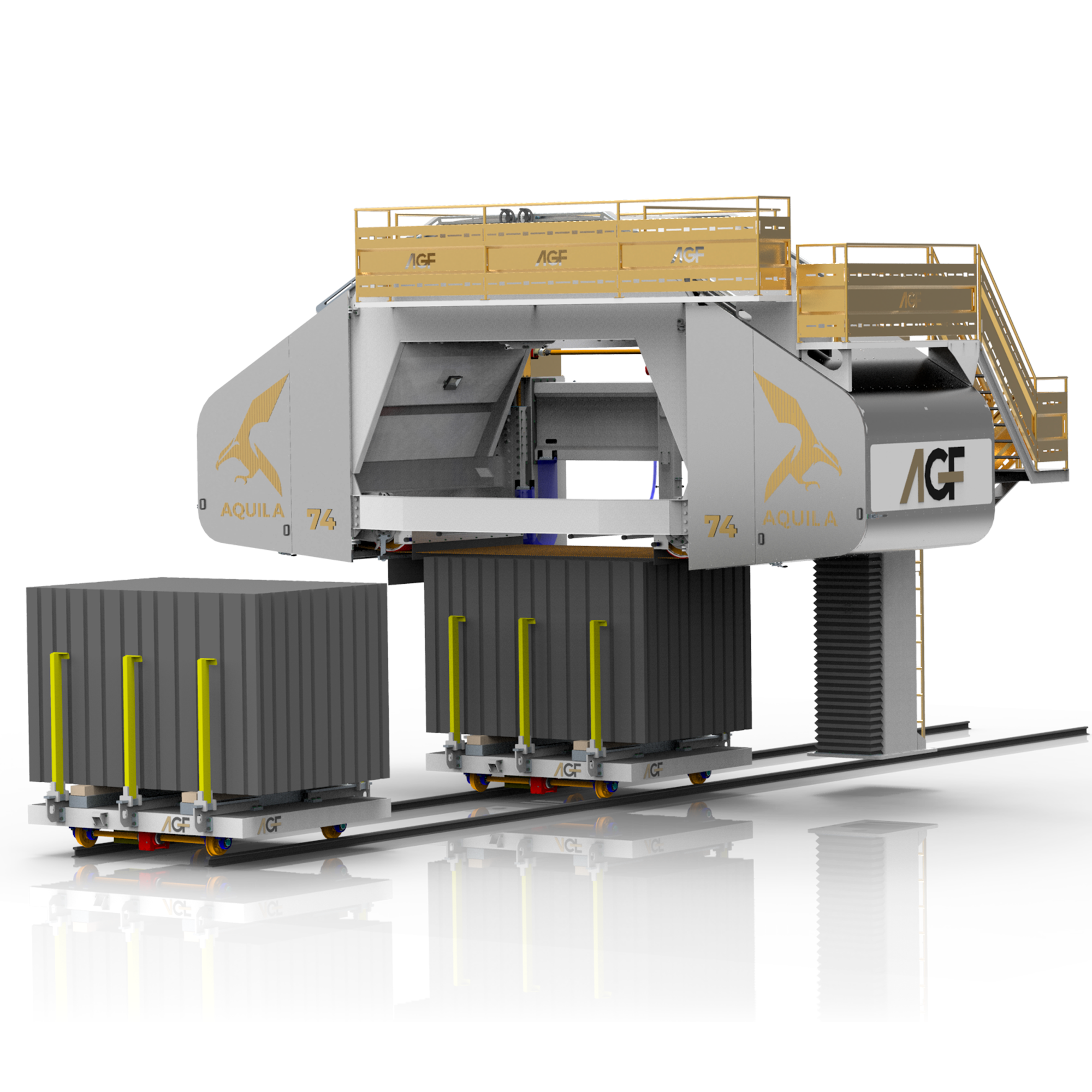

- Available in versions of 5, 6, 10, 16, 44, 54, 56, 74, 76, 86, and 90 wires, or according to the business necessity

- 5,3mm, 6,3mm, and 7,3mm wires can be applied

Robustness: Developed with high-durability materials, and with a project that avoids the components' wear and tear.

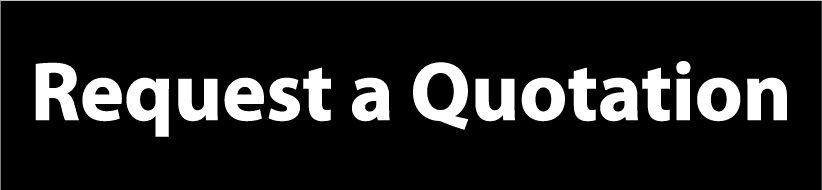

- Fairing, Stairs, and Walkways are manufactured in galvanized steel, which extends the equipment's lifetime

- Stainless steel fairing

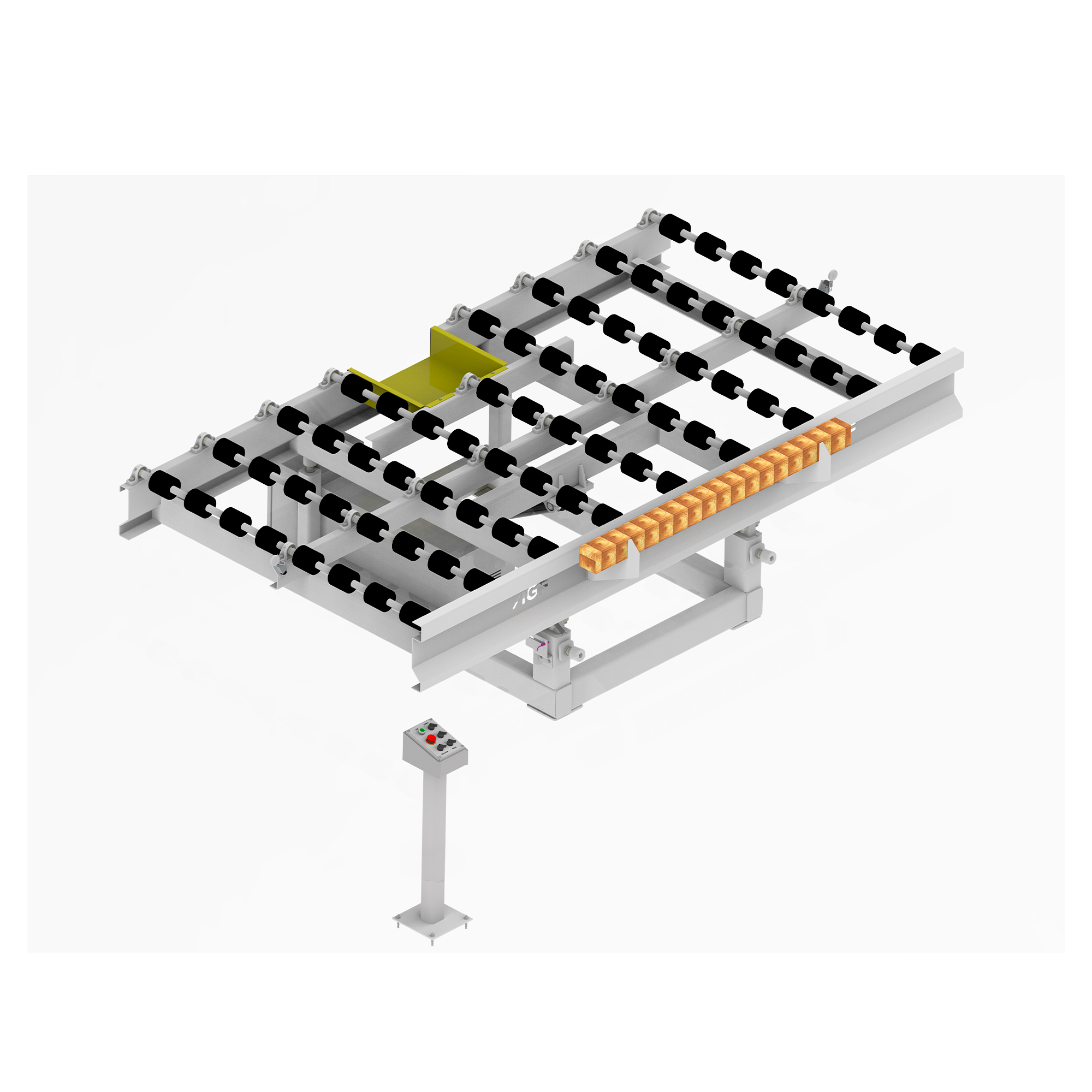

- 100% Aluminum Rolling System, which does not warp nor rust, guaranteeing the components' lifetime

- Rolling system set up over a hard-chrome axis, extending the equipment's lifetime

- Equipment designed to avoid axis overload, eliminating the risk of breaking.

Security: Designed to keep the personnel safe and preserve the machine

- Safe ladders and walkways for the operators' movement

- 16-Second Emergency Shutdown, increasing safety and reducing the chances of damage to the machine or wires - THE BEST SHUTDOWN TIME OF THE SEGMENT

- Protection sensors automatically stop the operation in case of hazard or equipment failure.

- Automatic checking and lubrication in 19 equipment points, preventing the operation in harmful conditions.

Innovation: 4.0 Industry Built-in

- Efficient management of the touch-screen panel

- Available in Portuguese, Spanish, English, Turkish, and easy to translate to other languages

- Intuitive Interface for total control of the equipment

- Full machine control through remote access (4.0 Industry) Except start-up operation

- Cutting plans and operations, energy and water consumption, and operation time management - generating key information for decision-making.

- Allows integration with Business Intelligence tool for better cutting operation view.